Product Description

Solution Description

WPC Great Wall Panel is a kind of “GreenerWood plastic composite substance” by mixing resin and wooden fiber components and polymer components in a specified proportion by way of substantial temperature, extrusion, molding and other processes, Artificial wooden.

WPC Great Wall Panel has the Eco-helpful, fast installation, high high quality and lower value, wooden texture, etc.,Welcome to customized.

Solution Information

| Solution Identify | WPC Grooved Grille |

| Material | Wooden Plastic Composite |

| Measurement | 192×12.4mm or Custom-made |

| Width | 192mm |

| Thickness | twelve.4mm |

| Length | 2.9m,3m or personalized |

| Area Colour | Wood Grain , Co-extrion |

| Installation | 1Glue on the sall 2 With Nails |

| Characteristics | Eco-welcoming, water-resistant, flame retardant, anti-scratch, long daily life, quick installation, substantial high quality and low cost, wood texture |

| Application | Inside Wall and Ceiling Decoration , like Hotel, Place of work buying mall living room, and many others |

Wpc Grille Background Advanatages :

Customized–We are the manufacturer! sample &OEM&ODM are offered!

Protection–We have very own take a look at chart, all of our items have been rigorously examined in the manufacturing facility.

Substantial Good quality –Our business makes use of the most innovative tools to make the very best quality products.

Application of WPC Fluted Wall Cladding

one. Interior decoration materials

Applied to a variety of wall panels, ceiling, siding, door frames, decorative articles, decorative

panels, framed pieces, curtain rods, sheet, curtain rings and decorative pieces, venetian blinds,

interior stairs, furniture (desks, chairs, windows countertops), lamps, etc.

2. Building materials

Can be used for indoor and outdoor decking, fence, door frames, wood tile, wood overall balcony,

sea floors, building templates, moisture separators, stairs, handrail, guardrail, road plates, BAN

cards, bike parking shed, room roof garden drainage board, anti-pipes and sites of ancient

structures, activity rooms, villas and so on.

WPC Wall Caldding Features:

one. Environmentally friendly, recyclable.

2. Looks and feels like nature wood.

3. Favorable mechanical performance, stable over a wide temperature range, weather resistant,

especially can be used in the open air.

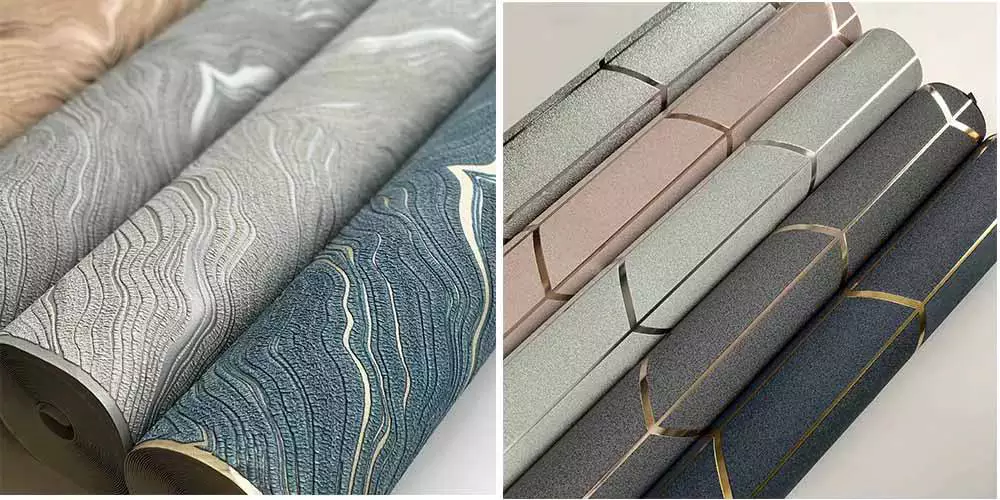

four. Brand range of appearance and color.

5. Cost low in maintenance.

6. Durable, economic.

seven. Easily and conveniently installed and cleaned.

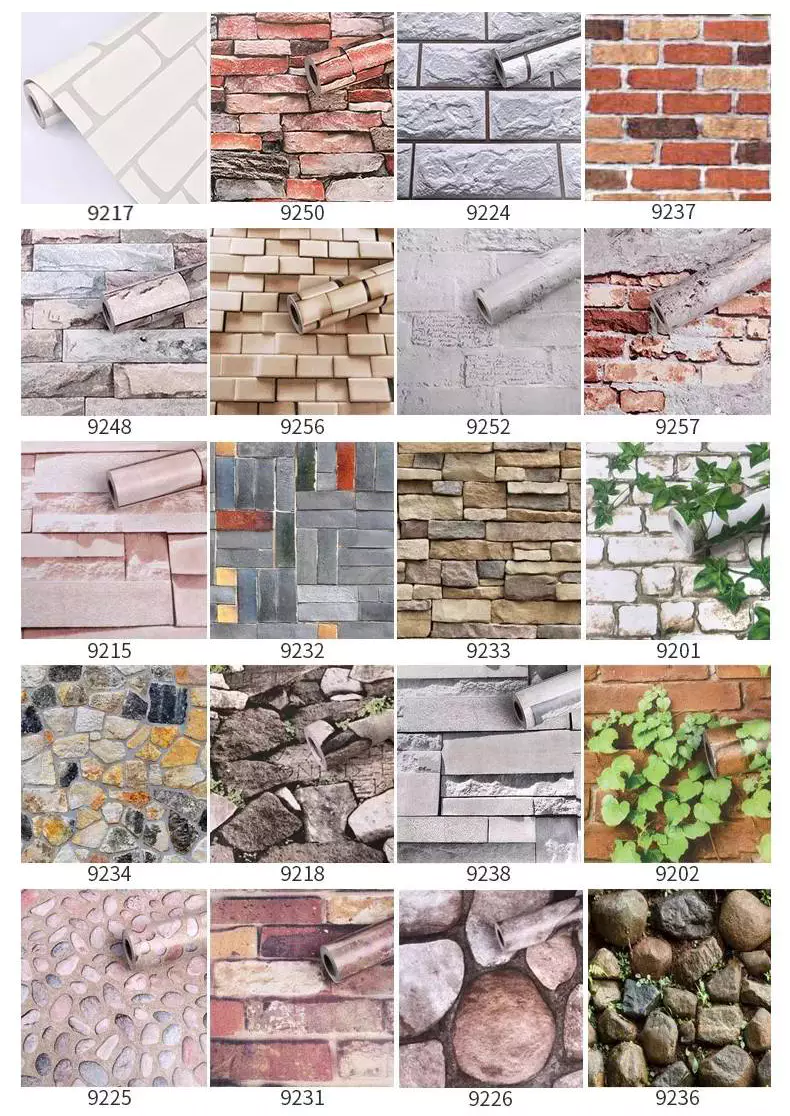

WPC Grooves Wall Panel Hues:

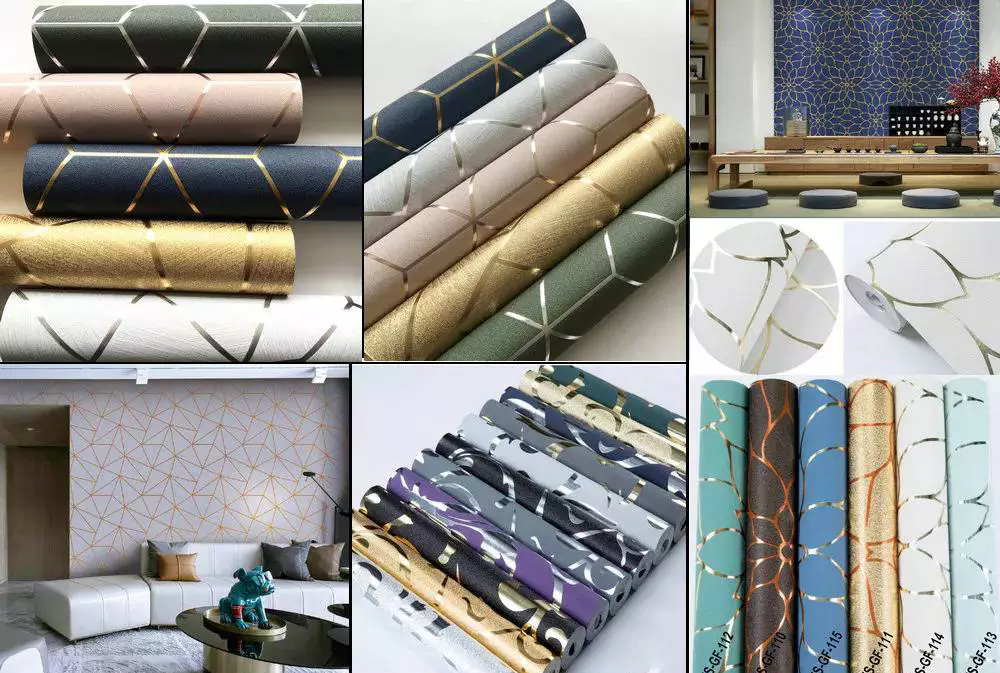

Related Item

More WPC Wall Cladding Design and styleAbout our Company

Our business HangZhou CZPT Co.,Ltd,We are expert maker and exporter of PVC decoration materials from China .

Our Products commonly use for family and industrial building’s interior decoration ,

With 3 Mainly Series : pvc Ceiling / pvc Wall Panels / SPC Flooring,WPC decking floor ,WPC inside wall board with go over almost all the region decoration need .

We have over 200 kinds of panel mould with in excess of 3000 coloration styles in our workshop ,so we can supply the panel by different width &Thickness&Length &Colour types&Toughness as purchase request.

With waterproof ,Termite proof,Fireplace retardant,Maintenance Free of charge,Easy Installation ,Cost-effective,Longevity,Anti-fungal Homes,Exceptional Climate-ability ,Modern coloration types and panel styles so a lot of rewards , our goods be welcome by different market place with their diverse decoration function.

Hyde business with superior management mode,item benefit and substantial top quality expertise staff to construct the core aggressive advantage,will be more integration of assets merchandise ,more thorough output of skilled goods,intense skilled channels,is dedicated to grew to become the major enterprises in decoration content business.

Edge of our company :

one.Encounter manufacturer over twenty A long time.

two.Protect almost industry panel producing mold and coloration styles

Length can make as normal 2.8m or customization

3.Take OEM/ODM Service,You can simple develop your very own model with our substantial top quality items.

four.Accept Item customization,but we advise that you have a particular buy amount,in any other case the price of the mould will be increased.

five.Take Colour Customization

six.Free Sample (Sample will be cut by little piece with dimension not use for installation , only for examine quality.welcome make contact with us if you need to have sample .)

seven.24 Hrs On-line Services

eight.Thorough goods protection,like pvc ceiling/pvc wall panel/matching equipment/SPC ground,etc.Buyers can obtain in our organization jointly,saving logistics charges and time.

|

US $1.60-2.48 / Meter | |

2,000 Meters (Min. Order) |

###

| After-sales Service: | Online Service |

|---|---|

| Warranty: | 5 Year |

| Material: | WPC |

| Usage: | Indoor |

| Customized: | Customized |

| Pattern: | Wooden, Marble, White, Grain, Co-Extrusion |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Product Name | WPC Grooved Grille |

| Material | Wood Plastic Composite |

| Size | 192×12.4mm or Customized |

| Width | 192mm |

| Thickness | 12.4mm |

| Length | 2.9m,3m or customized |

| Surface Color | Wood Grain , Co-extrion |

| Installation | 1Glue on the sall 2 With Nails |

| Features | Eco-friendly, waterproof, flame retardant, anti-scratch, long life, quick installation, high quality and low price, wood texture |

| Application | Interior Wall and Ceiling Decoration , like Hotel, Office; shopping mall; living room, etc |

Types of Wall Coverings

Choosing the right wall covering is not just about style, but also about durability and maintenance. You need to choose something that will stand up to frequent washing and dry cleaning. There are several types of wall coverings, including Vinyl, fabric, and chalkboard.

Fabric

Using a fabric wall covering is a great way to add style to your home. These coverings come in all sorts of colors, shapes, and designs. They add warmth to a room and help to absorb sound. They also have the added bonus of being easier to install than traditional wallpaper. They can be found in many different materials, including cotton, leather, and linen. They can be customized to match your home’s decor.

One of the most popular fabrics is velvet. This material has been proven to be durable and stain-resistant. It also adds a unique texture to your wall.

Fabric wall coverings are usually used in rental situations or where wallpaper is not allowed. They can also be used in conjunction with wallpaper. They can be installed on cement walls.

Another good reason to use fabric on your walls is to create a decorative frame. This can be done with a fabric panel or a decorative frame made of wood or MDF furring.

When purchasing a fabric wall covering, make sure to check with the seller for maintenance instructions. A fabric wall covering will need regular cleaning. You may also want to invest in a protective material, such as a liquid starch. You can also use a brush to keep the fabric in good shape.

A fabric panel can be attached to the wall using velcro strips or removable tacks. This method is highly durable and easy to maintain.

Vinyl wallpaper

Using vinyl wallpaper as a wall covering is a great way to give a room a special appearance. It is easy to install, washable, and comes in a wide variety of styles. It is perfect for residential properties and also for business establishments.

Vinyl wallpaper is made from a vinyl compound and a carrier material. The outer surface of the wallpaper can be embossed, textured, and paintable. You can also find wallpaper with relief patterns and bright highlights.

Vinyl wallpaper can be installed in wet areas, such as bathrooms, and kitchens. It is also a great way to reduce renovation costs in the restaurant industry. It is also a good option for decorating the risers of stairs.

Vinyl wallpaper has several advantages, but some disadvantages. It can contain dangerous pollutants, such as carcinogens. It is also easy to damage. There are also hazards from plasticisers, which enter through the skin. The walls of a home are also susceptible to pollutants, such as volatile organic compounds (VOCs).

There are two main types of vinyl wallpaper: washable and non-washable. Washable wallpaper can be soaked in water or treated with a damp cloth. It is easier to clean than other types of wallpaper.

Non-washable wallpaper can be soaked in warm water and a damp cloth. You can also buy a ready-mixed paste. If the wallpaper is very heavy, you will have to use a special paste. You will also have to sand the wallpaper before installing it.

Wood

Whether you are looking for a rustic feel for your home or a vintage look for your office, wood paneling is a unique way to incorporate nature into your home. Using real wood or vinyl paneling can add a rustic flair to any room.

Panelling is traditionally made of interlocking pieces of wood. However, there are other material options such as plastic or even vinyl that can mimic the look of wood.

As you consider the options for your home, you should choose the wall covering that best suits your taste. It will set the tone for your interior scheme. You can also use wall panels to add insulation and soundproofing to your walls. Wall coverings are also an effective way to repair damaged walls.

There are many different types of wall coverings, each one having its own strengths and drawbacks. Wood paneling is a versatile and cost-effective option, though it is also susceptible to moisture damage.

You can choose from a range of materials, including solid wood, MDF and reclaimed wood. Depending on your needs, you may want to choose a wall covering that can be easily installed or a more durable option.

You can also choose from a variety of finishes, including glossy, matte and UV Oiled. This will allow you to match the wood paneling with your decor.

If you want a more affordable option, consider plywood. You can easily cut and install plywood to mimic the look of a plank wall. It is also easy to repair.

Chalkboard wall

Using a chalkboard wall covering can be fun, but it can also be a pain. Unlike the chalkboards of yore, modern chalkboards are attached to vertical surfaces, which can be particularly problematic. Additionally, chalkboard surfaces tend to disengage from their supporting surfaces over time. Hence, the invention aims to create a chalkboard that lasts longer, is easier to remove, and is more cost effective to manufacture.

The invention is comprised of a chalkboard-like marking surface constructed from a sheet of polypropylene. This sheet is paired with a small sheet of adhesive. The adhesive is a low-tack variety, meaning that it is not likely to damage the surface. It may also be pre-applied to the substrate sheet.

The invention also features a protective liner that is attached to the adhesive on the back side of the sheet. The liner is large enough to prevent foreign materials from attaching to the adhesive layer, but small enough to be easily removed by the user. The liner may also serve to retain a bit of extra weight, which may be of interest to the user.

The invention also features a small, light-weight chalkboard that is easy to move and store for future use. It has the aforementioned benefits, and can also be used to mark up a wall, table, or door. It is also more durable than its predecessors.

As a result, the invention can be used to mark up a wall, tabletops, doors, or even your desk. The invention is also more environmentally friendly than its predecessors because it is made from a recyclable material.

Double cut seam

Using a double cut seam wall covering can help you repair holes and wrinkles in the wallcovering. This is a process that involves cutting a square piece of wallcovering and holding it in place to create a patch to fit the hole.

This method will ensure that the pattern matches properly and that the seams are in the correct places. However, this method is time consuming. It also requires a sharp utility knife and special tools.

First, remove the top layer of wallpaper and then remove the inner layer of paper. Be careful not to cut through the drywall. A razor blade can also be used to cut the primer. Once the outer layer of paper is removed, use a sponge or folded towel to smooth out the surface.

Next, apply a liquid paper remover to the surface. Use a painters’ mask to apply the solution to the wall covering. This will help soften the paper adhesive and will allow you to remove the trapped air.

After the paper is removed, you should apply powdered vinyl adhesive to the wall. This will help prevent the fabric from stretching and shrinking.

Finally, apply a thin coat of adhesive to the back of the patch and then roll the patch onto the wall. This will help smooth the adhesive and prevent blisters.

Leaving the old wall covering on will likely leave you with blisters on your wall. These blisters are caused by trapped air within bubbles in the adhesive. They can appear days after the project has been completed. The easiest way to deal with them is to prevent them.

Maintenance

Putting a little effort into a well thought out wall maintenance plan will yield significant savings. This is especially true as wall coverings are not only exposed to natural elements but also indoor pollutants. A well thought out plan will also reduce downtime when it comes to repairs and replacements.

There are several ways to keep your walls looking their best. From installing new wall coverings to cleaning them on a regular basis, there are several considerations to keep in mind. The most obvious is the material used to cover your walls. Using a hardwearing material will prolong the life of your wall coverings. Also, a good quality wall covering will not show signs of wear and tear.

For the most part, the most impressive thing to do in regards to wall coverings is to keep the surface as clean as possible. It may also help to seal the wall surface with a waterproofing product. In this way, you can avoid scuffs and scratches.

Using a non-toxic cleaner on a regular basis is also a smart move. The cleaner should be used from the bottom of the wall up. It should also be allowed to soak for a few minutes. A thorough cleaning will not only keep your walls looking new but also will keep them smelling fresh. A clean surface will also help keep bacteria at bay.

The best wall coverings are the ones that can stand the test of time. Using the correct maintenance products and processes will make this easy to accomplish.

editor by CX 2023-06-27